For woodworkers and DIY enthusiasts, the selection of materials can be the difference between success and failure of the outcome of a project. Solid wood is a classic material, however engineered wood products such as MDF (Medium Density Fibreboard) Melamine, particle and boards are an excellent alternative. Understanding the specific properties of each product and applications is vital to achieving beautiful and functional results.

MDF Board: Smoothness, The Champion and Versatility!

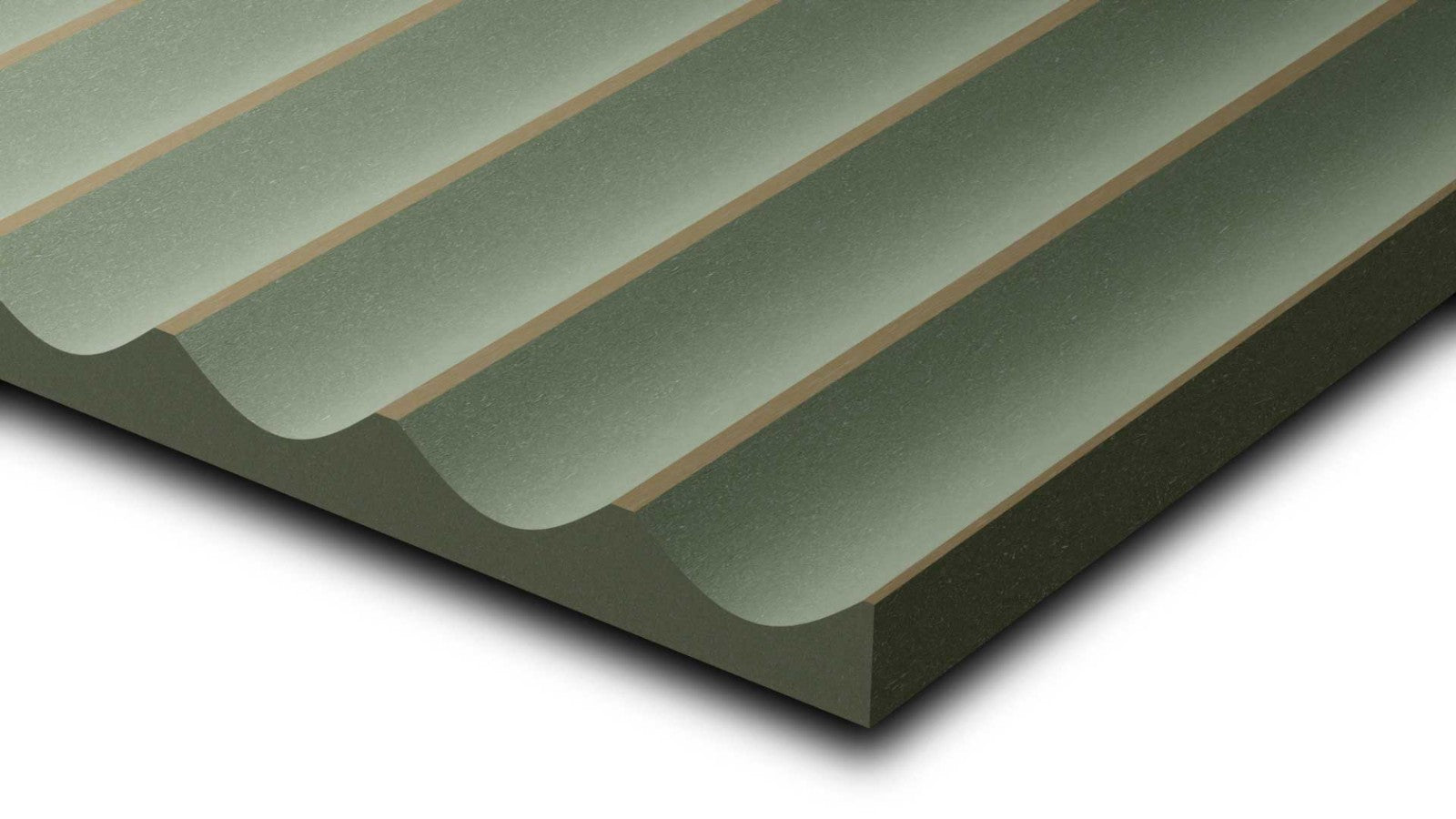

MDF has become a staple in woodworking workshops around the world. The smooth and uniform surface makes it easy to paint, stain or even apply veneers. MDF boards are a lot more durable than solid wood, which makes them less likely to warp or crack. The consistency of MDF makes it ideal for intricate carvings and moldings.

The Benefits of Using MDF Boards:

Smooth Surface: This permits the painting or veneer that is perfect, giving a professional finish.

Efficiency: MDF board is easy to cut, drill and run out. This makes it ideal for intricate designs.

MDF Boards are strong and durable: MDF boards of high quality can withstand daily wear and tear as well as moisture regardless of their appearance.

Versatility: From crafting furniture, to making cabinets and even constructing architectural elements, MDF boards have a diverse range of applications.

Melamine Sheets – Where strength meets fashion

Melamine sheets take MDF boards one step further by adding the appearance of a decorative element. They are made of a thin layer MDF with melamine resin, which is then joined to form a visually attractive and durable surface. Melamine finishes are available in a vast array of textures, colors, and woodgrain patterns, which allows you to get the desired aesthetic to your design.

The benefits of Melamine Sheets

Scratch- and stain-resistant: The melamine finish offers an excellent level of resistance to scratches, staining and fade. They are suitable for areas with high traffic, such as bathrooms and kitchens.

Easy Maintenance: Melamine sheets require minimal upkeep. They are maintained by a quick wipe down using a damp towel.

Melamine sheets are a cost-effective alternative to solid wood. They look just as great, but they’re much more affordable.

Multiple applications from kitchen cabinetry and countertops, to wall panels and furniture, the flexibility of Melamine sheets makes them an ideal choice for both residential and commercial projects.

Particle Boards: A Economical Alternative

While it’s not as well-known as MDF or melamine, the particle board is an excellent choice for projects that value the structural integrity of the project over aesthetics. Particle board is made from wood fibers, which are pressed and then put together with resin. It is a great level of stability and strength.

Understanding Particle Board:

Cost-Effective: Particle board is the most affordable option among the three mentioned.

Application Limitations: The particle board’s rougher surface and low humidity resistance make it ideal for use in areas where aesthetics are not the main concern. Examples include interior furniture parts and subflooring.

When exposed to moisture particles of board will expand and lose the structural integrity. In humid conditions it is essential to choose types that are resistant to moisture.

Choosing the appropriate engineered wood panel

Selecting the right engineered panel for your project will depend on its specific needs and objectives. This is a brief guide to help you select:

MDF boards offer a smooth finish as well as intricate designs and flexibility.

Melamine sheets are the ideal option when toughness, scratch resistance and an unfinished surface are essential.

If you are looking for projects that are cost-conscious and where structural integrity is the main concern, particleboard can be an alternative.

The Future of Woodworking is Embracing Engineered Wood.

MDF sheets, melamine sheets and particle board are excellent options for DIYers as well as woodworkers. Their cost-effectiveness, flexibility, and consistent performance make them valuable additions to the toolbox of any project. We are likely to see more and more unique engineered solutions emerge with the advancement of technology. This will further expand the possibilities for creativity in the future of woodworking.